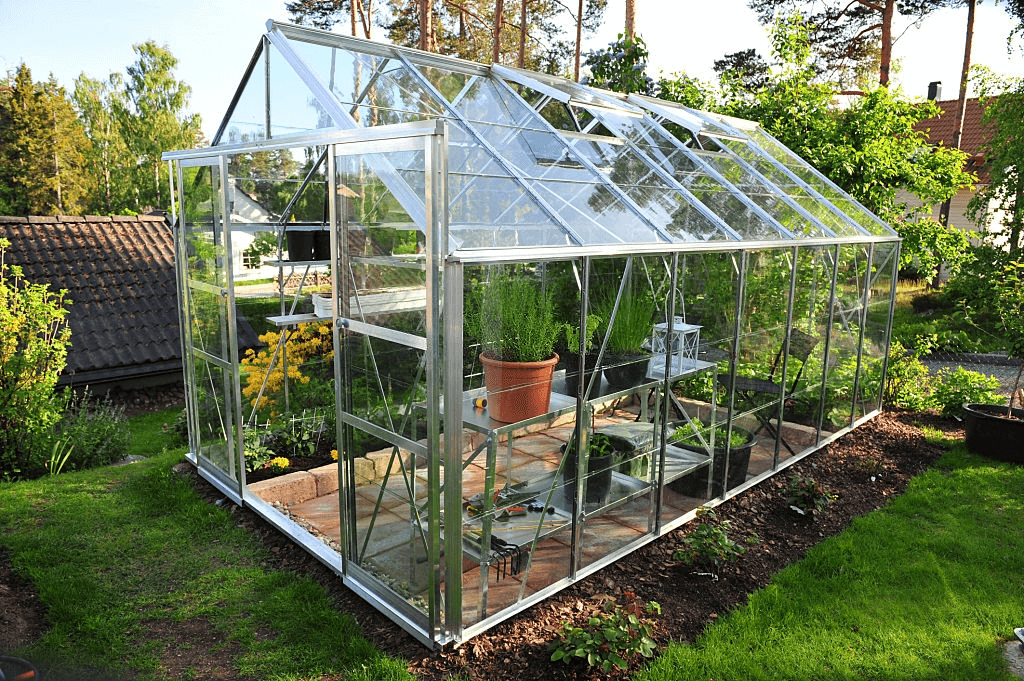

Is Perspex ok for a greenhouse? A Comprehensive Guide to Using Perspex in Your Garden Space

As gardening enthusiasts seek innovative solutions for enhancing their garden spaces, the use of Perspex, a brand of acrylic sheet, is gaining popularity as an alternative to traditional greenhouse materials. This comprehensive guide examines the advantages and disadvantages of using Perspex for greenhouses, including its durability, insulation properties, and light transmission capabilities. By understanding how Perspex compares to glass and other materials, gardeners can make informed decisions tailored to their specific needs. Delve into the practicalities of incorporating Perspex into your greenhouse design and discover whether it's the right choice for your gardening ambitions.

Is Perspex Suitable for a Greenhouse?

Perspex, also known as acrylic or plexiglass, is considered a viable option for greenhouse construction due to its excellent light transmission capabilities, which can be comparable to glass. It is lightweight, making it easier to handle and install than traditional glass panels. Additionally, Perspex is durable and resistant to UV radiation, which protects plants from excessive exposure while allowing sufficient sunlight to penetrate. However, it is essential to consider its potential drawbacks, such as susceptibility to scratches and structural weaknesses against extreme weather conditions. Regular maintenance and proper installation techniques can enhance its effectiveness as a greenhouse material.

Advantages of Using Perspex in Greenhouses

One of the primary advantages of using Perspex in greenhouses is its remarkable clarity and light transmittance, allowing more than 90% of sunlight to enter. This can lead to enhanced plant growth and productivity. Moreover, Perspex is much lighter compared to glass, which means less structural support is required, reducing construction costs and time. Furthermore, its insulating properties can help maintain a stable temperature inside the greenhouse, leading to a more suitable environment for plants.

Disadvantages of Perspex for Greenhouses

Despite its advantages, Perspex also has certain disadvantages such as its vulnerability to scratches and potential for yellowing over time with prolonged exposure to sunlight. This can affect both its appearance and effectiveness. Additionally, while Perspex is known for its durability, it may not withstand extreme weather elements as effectively as glass, leading to possible cracking or breakage in severe conditions. Regular checks and replacement might be necessary to ensure optimal performance.

Comparison with Glass Greenhouses

When comparing Perspex to traditional glass greenhouses, both have unique features that may cater to different gardening needs. Glass offers superior strength and is generally more resistant to scratching, making it ideal for enduring harsher climates. However, it is heavier and may require more robust structural support. On the other hand, Perspex provides an incredible advantage in terms of weight, versatility, and ease of installation, although it may need more maintenance and care in certain situations. Overall, the choice between the two will largely depend on individual preferences and specific growing conditions.

Maintenance Tips for Perspex Greenhouses

Maintaining a Perspex greenhouse involves several key practices to prolong its life and effectiveness. Regular cleaning is crucial to preserve its clarity and prevent the build-up of dirt and debris on its surface. It is advisable to use a mild soap solution instead of abrasive cleaners, which can damage the material. Additionally, checking for scratches and applying protective coatings can help to enhance its durability. It is also essential to inspect the structure periodically to ensure that it remains secure and can withstand environmental factors over time.

Cost Considerations for Perspex Greenhouses

The cost of building a greenhouse using Perspex can vary significantly based on various factors, including the size of the structure and the type of acrylic used. Generally, Perspex greenhouses tend to be less expensive than their glass counterparts due to lower material and installation costs. However, prospective buyers should also account for long-term maintenance costs, as scratches and wear can necessitate replacement or repairs. Proper budgeting will ensure that all aspects of construction and upkeep are considered, leading to a successful greenhouse venture.

| Feature | Perspex | Glass |

|---|---|---|

| Light Transmission | Over 90% | About 90% |

| Weight | Lightweight | Heavy |

| Durability | Moderate | High |

| Scratch Resistance | Low | High |

| Cost | Lower | Higher |

Can you use Perspex in a greenhouse?

Yes, you can use Perspex (also known as acrylic) in a greenhouse. Perspex is a type of plastic that is often chosen for its clarity and durability, making it appealing for greenhouse applications. Here are some reasons why it can be beneficial, along with considerations to keep in mind.

Advantages of Using Perspex in Greenhouses

Using Perspex in greenhouses comes with several advantages that make it a popular choice among gardeners and horticulturists.

- Light Transmission: Perspex allows for about 92% light transmission, which is crucial for plant growth.

- UV Resistance: Many grades of Perspex block harmful UV radiation, helping to protect plants from damage.

- Weight: Perspex is much lighter than glass, making it easier to install and manipulate.

Disadvantages of Using Perspex in Greenhouses

While Perspex has many benefits, there are also disadvantages that should be considered before installation.

- Scratching: Perspex surfaces can be prone to scratches, which may obstruct light over time.

- Temperature Variability: Perspex can expand and contract with temperature fluctuations, which may lead to structural issues.

- Cost: Perspex can be more expensive than traditional glass options, impacting budget considerations.

Maintenance Requirements for Perspex Greenhouses

Maintaining a Perspex greenhouse is different compared to other materials, and specific care should be taken.

- Cleaning: Use a gentle cleaner and soft cloth to avoid scratching the surface.

- Inspection: Regularly check for signs of wear, such as yellowing or cracking, to ensure longevity.

- Sealants: Consider using appropriate sealants to prevent moisture ingress at joints.

Perspex vs. Traditional Glass Greenhouses

Comparing Perspex to traditional glass reveals significant differences in properties and performance.

- Imact Resistance: Perspex is less likely to shatter than glass, providing increased safety.

- Insulation: Perspex typically offers better insulation properties compared to single-pane glass.

- Customizability: Perspex can be easily cut and shaped, allowing for unique greenhouse designs.

Types of Plants Suitable for Perspex Greenhouses

Choosing the right plants for a Perspex greenhouse can optimize growth and health.

See also:

- Tropical Plants: These often benefit from the higher humidity levels maintained in a Perspex structure.

- Vegetables: Fast-growing vegetables can thrive with the optimal light conditions provided by Perspex.

- Ornamental Plants: Many decorative plants appreciate the stable environment of a Perspex greenhouse.

What are the disadvantages of Perspex?

The disadvantages of Perspex, also known as acrylic, are important to consider, especially when choosing materials for manufacturing or design. Although it offers various advantages, such as transparency and lightweight properties, there are some notable downsides that can affect its usability and longevity.

Poor UV Resistance

One of the significant drawbacks of Perspex is its relatively poor UV resistance. Over time, exposure to ultraviolet light can lead to discoloration and degradation of the material, which may affect its appearance and mechanical properties. While some formulations may have UV stabilizers, they do not eliminate the problems entirely. This can be particularly concerning for applications exposed to direct sunlight.

- Discoloration over time under prolonged sunlight.

- Reduced clarity, impacting aesthetic appeal.

- Potential cracking or brittleness due to UV exposure.

Impact Resistance Limitations

Despite being more impact-resistant than glass, Perspex has its limits. While it may withstand certain impacts, it can still fracture or shatter under high force or stress conditions. This limitation can be detrimental in applications where high durability is a requirement.

- Not suitable for heavy-duty applications.

- Potential safety risks if broken shards are involved.

- Limited applications in environments prone to high impact.

Scratching Vulnerability

Perspex is more prone to scratching than glass, which can compromise its clarity and aesthetic appeal. Even minimal contact with abrasive materials can lead to surface damage, making it less suitable for applications where a pristine surface is essential. This vulnerability necessitates careful handling and maintenance, increasing the overall effort required to keep it looking new.

- Requires regular cleaning and special care to maintain clarity.

- Potential costs involved in replacement or repair.

- Not ideal for high-traffic areas where scratches can accumulate quickly.

Thermal Limitations

Perspex has a lower thermal resistance compared to other materials like polycarbonate. It can warp or deform when exposed to high temperatures. This characteristic limits its applications in environments where heat exposure is common, as it may not maintain its structural integrity under such conditions.

- Not suitable for outdoor applications in hot climates.

- Deformation risks during manufacturing processes requiring high heat.

- Limited durability in environments with temperature fluctuations.

Environmental Impact

The environmental impact of Perspex also raises concerns. It is not a biodegradable material, leading to potential waste management issues. Upon disposal, acrylic can persist in landfills for a very long time, contributing to overall environmental waste. This aspect can be a significant disadvantage for companies looking for sustainable materials.

- Challenges in recycling and waste disposal.

- Potential contributions to plastic pollution.

- Less attractive option for environmentally conscious consumers.

What type of plastic is best for a greenhouse?

The best type of plastic for a greenhouse is polycarbonate or polyethylene. Both materials have their own advantages and should be chosen based on specific needs such as climate, budget, and the plants being grown.

Polycarbonate Greenhouse Panels

Polycarbonate is a durable and lightweight material often utilized in the construction of greenhouses. It offers superior insulation and can handle extreme weather conditions.

- Insulation: Polycarbonate panels provide excellent thermal insulation, reducing heating costs during the winter months.

- Impact Resistance: This type of plastic is incredibly impact-resistant, making it less likely to break compared to glass.

- UV Protection: Many polycarbonate panels come with a UV-resistant coating, which helps protect plants from harmful sun rays while allowing adequate light penetration.

Polyethylene Greenhouse Film

Polyethylene, often referred to as poly film, is another popular choice for greenhouses. It is affordable and easy to install, making it a favored option among hobby gardeners.

- Cost-Effective: Polyethylene film is one of the most budget-friendly greenhouse covering materials available.

- Flexibility: This film is versatile and can be easily cut to fit different greenhouse structures or shapes.

- Light Diffusion: Polyethylene offers good light diffusion, which can enhance plant growth by distributing sunlight evenly.

Comparing Durability

Durability is a critical factor when choosing plastic for greenhouses, as it affects the longevity of the structure.

- Polycarbonate Longevity: Polycarbonate panels can last up to 10-20 years with proper care, making them a long-term investment.

- Polyethylene Lifespan: In contrast, polyethylene film typically lasts about 4-6 years before needing replacement.

- Weather Resistance: Polycarbonate offers better resistance to extreme weather compared to polyethylene, which can degrade faster when exposed to harsh conditions.

Climate Considerations

The climate in which the greenhouse is located significantly influences the choice of plastic.

- Cold Climates: Polycarbonate is preferred in colder regions due to its superior insulation properties.

- Warm Climates: In hotter areas, a double-layer polyethylene with an air pocket can help mitigate heat buildup.

- Humidity Levels: Humid climates may also favor polycarbonate, as it is less prone to mold and degradation compared to polyethylene.

Environmental Impact

The environmental impact of the plastic used for greenhouses is an important consideration in today's sustainable practices.

See also:

- Recyclability: Polycarbonate is more difficult to recycle compared to polyethylene, which can be recycled more easily.

- Energy Efficiency: The insulation properties of polycarbonate can result in reduced energy consumption, making it an environmentally friendly option.

- Life Cycle Assessment: Consideration of the entire life cycle of the materials, from production to disposal, is crucial in assessing their environmental impact.

Can Perspex withstand heat?

Perspex, also known as acrylic or polymethyl methacrylate (PMMA), is a popular transparent thermoplastic used in various applications. One of the common questions regarding Perspex is its ability to withstand heat.

Can Perspex Withstand Heat?

Perspex can withstand moderate heat, but it has a limit. The thermal properties of Perspex allow it to endure temperatures up to approximately 100 degrees Celsius (212 degrees Fahrenheit) without deforming. However, exposure to higher temperatures can lead to changes in its physical properties and structural integrity.

Even though Perspex is somewhat resistant to heat, it is not entirely heat-proof. Prolonged exposure at elevated temperatures will cause warping, bubbling, or even melting in extreme cases. Consequently, it's crucial to evaluate the specific requirements of your application before using Perspex in environments exposed to heat.

Properties of Perspex Regarding Heat Resistance

The heat resistance of Perspex can be attributed to different factors, including its material composition and thickness.

- The melting point of Perspex is around 160 degrees Celsius (320 degrees Fahrenheit).

- Thin sheets of Perspex may deform more easily compared to thicker counterparts at similar temperatures.

- Plasticizers or additives in certain types of Perspex can influence heat resistance, thus altering their performance in heated environments.

Applications Suitable for Perspex in Heated Environments

While Perspex does have limitations regarding heat exposure, it is suitable for several applications where heat is a factor, including:

- Light fixtures: Used in locations that do not exceed the temperature threshold.

- Protective covers for machinery: Can be utilized if temperatures are monitored accurately.

- Display cases: Often used in exhibitions but should be kept away from direct heat sources.

Comparing Perspex to Other Materials

When considering heat resistance, it's essential to compare Perspex with other materials:

- Glass: Generally offers a higher heat resistance but may shatter under rapid temperature changes.

- Polycarbonate: Provides better heat resistance than Perspex, making it a suitable alternative in high-temperature applications.

- ABS plastic: Can withstand lower temperatures compared to Perspex, often used in applications needing moderate heat resistance.

Best Practices for Using Perspex in High-Temperature Areas

When utilizing Perspex in environments where heat is a concern, following best practices can enhance performance:

- Limit exposure: Keep Perspex away from direct heat sources to prolong its lifespan.

- Monitor temperature: Use in well-ventilated areas and maintain temperatures below recommended limits.

- Reinforcement: Consider using thicker sheets for applications that might be exposed to fluctuating heat.

Limitations of Perspex in Heat Applications

Understanding the limitations of Perspex will aid in making informed decisions:

- Deformation risk: At elevated temperatures, the risk of physical deformity increases significantly.

- Chemical vulnerabilities: Certain chemicals and heat can result in brittleness or discoloration.

- Not fire-resistant: Perspex is not a fireproof material, and flames or high-temperature contact can lead to potential hazards.

Questions from Our Readers

Is Perspex suitable for greenhouse construction?

Perspex, also known as acrylic, is a good option for greenhouse construction due to its excellent light transmission and durability. It provides up to 92% of visible light, which promotes plant growth. However, it is essential to ensure that it is UV-protected to prevent yellowing and degradation over time.

How does Perspex compare to traditional glass for greenhouses?

While traditional glass is heavy and can break easily, Perspex is significantly lighter and more shatter-resistant. This makes it easier to handle and install. However, glass typically offers better insulation and scratch resistance than acrylic, which can be a consideration depending on your greenhouse climate needs.

Can Perspex withstand harsh weather conditions?

Yes, Perspex is quite resilient and can withstand various weather conditions, including rain, snow, and strong winds. However, prolonged exposure to high temperatures may cause it to warp or degrade, so proper ventilation is crucial in maintaining the integrity of the greenhouse.

Is Perspex more expensive than other materials?

Generally, Perspex can be more expensive than options like polycarbonate or plastic sheeting. However, its long-term benefits, such as durability and light transmission, can justify the higher initial investment for many gardeners looking for a reliable greenhouse material.

See also:

If you want to read more articles like Is Perspex ok for a greenhouse? A Comprehensive Guide to Using Perspex in Your Garden Space, we recommend you check out our Greenhouse category.

Leave a Reply

Related Articles