Can I Use Corrugated Plastic for a Greenhouse? Pros, Cons, and Best Practices

When it comes to building a greenhouse, selecting the right materials is crucial for ensuring optimal growth conditions for your plants. Corrugated plastic has emerged as a popular choice among gardeners due to its lightweight nature and durability. However, potential users often wonder about the pros and cons of using this material for greenhouse construction. In this article, we will explore the benefits and drawbacks of corrugated plastic, examine its suitability for greenhouses, and provide best practices for its use, helping you make an informed decision on whether it’s the right option for your gardening needs.

Can I Use Corrugated Plastic for a Greenhouse?

Yes, you can use corrugated plastic for a greenhouse, and it is a popular choice due to its durability, lightweight nature, and excellent insulation properties. This material, often made from polycarbonate or polypropylene, provides a good balance between sunlight transmission and thermal retention, promoting plant growth effectively. Moreover, corrugated plastic is resistant to impacts and UV rays, making it suitable for long-term use in various climatic conditions. It is important to consider factors such as the thickness of the sheets, the potential for condensation, and the overall structural integrity of the greenhouse when using this material.

Benefits of Using Corrugated Plastic

Using corrugated plastic offers several benefits for greenhouse construction. It provides lightweight yet strong panels that are easy to handle and install. The corrugated design allows for better rigidity and structural integrity while also enhancing light diffusion. Furthermore, it offers excellent insulation, reducing heating costs during colder months and helping to maintain a stable environment for plant growth.

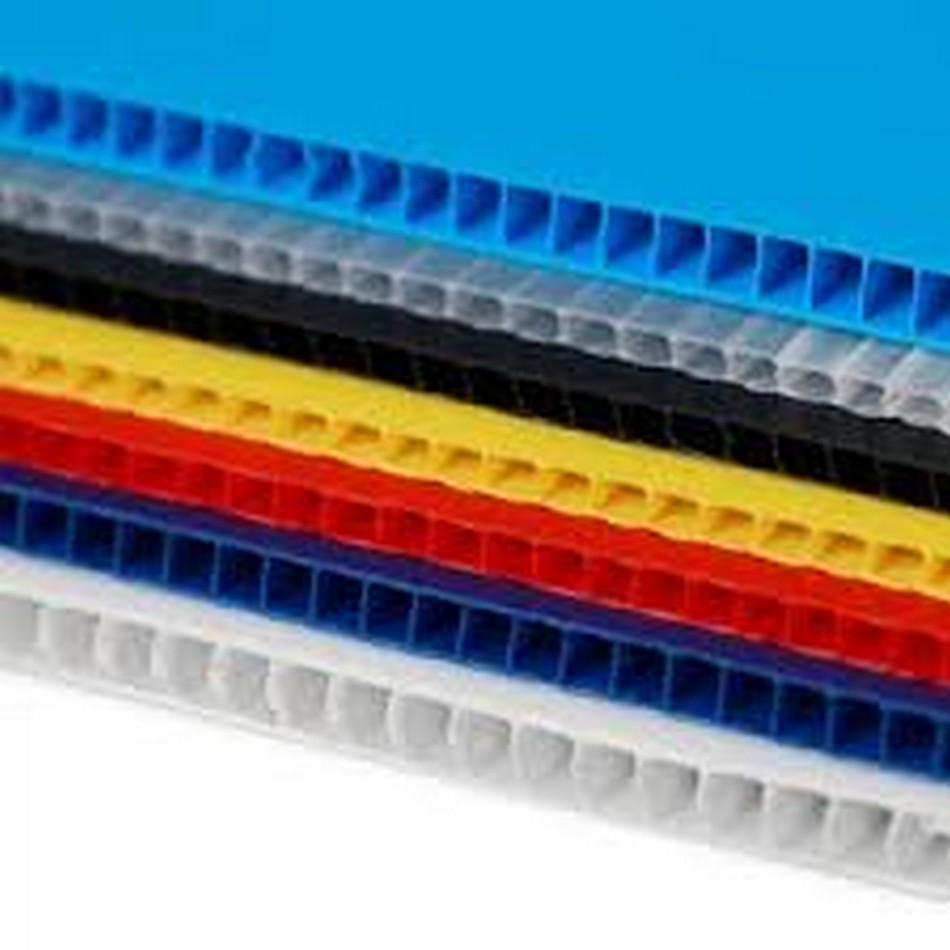

Types of Corrugated Plastic

There are various types of corrugated plastic available for greenhouse use, most commonly made from polycarbonate and polypropylene. Polycarbonate sheets are known for their high impact resistance and superior insulation properties, making them ideal for regions with extreme weather. On the other hand, polypropylene sheets are more affordable and provide adequate durability for less demanding climates. Both options are flexible in terms of thickness and can be cut to fit specific greenhouse designs.

Installation Considerations

Installing corrugated plastic panels requires careful consideration to ensure maximum efficiency and durability. It's essential to use appropriate fasteners and sealing kits to prevent air and water leaks. Additionally, panels should be oriented correctly to facilitate proper drainage and to avoid water accumulation, which can potentially weaken the structure over time. Insulation features should also be evaluated to prevent condensation buildup inside the greenhouse.

Maintenance of Corrugated Plastic Greenhouses

Maintaining a greenhouse made from corrugated plastic involves regular cleaning and inspection to ensure longevity. Over time, dirt and debris can accumulate on the panels, reducing their ability to transmit sunlight. Using a soft cloth with mild soap and water can help in maintaining clarity. Additionally, checking for any cracks or damages periodically is essential, as these can compromise the greenhouse's structural integrity and thermal efficiency.

Cost-Effectiveness of Corrugated Plastic

Investing in corrugated plastic for greenhouses can be quite cost-effective when considering both upfront costs and long-term benefits. While initial expenses may vary based on the material type and thickness, the durability and low maintenance requirements often lead to lower replacement costs over time. Additionally, the energy efficiency provided by effective insulation can reduce heating expenses, making it a wise choice for greenhouse owners looking to optimize their budget.

| Feature | Polycarbonate | Polypropylene |

|---|---|---|

| Impact Resistance | High | Medium |

| UV Resistance | Excellent | Good |

| Insulation | Superior | Moderate |

| Weight | Lightweight | Very Lightweight |

| Cost | Higher | Lower |

Is corrugated plastic ok for a greenhouse?

Yes, corrugated plastic is commonly used in greenhouses and is considered a suitable option for various reasons. This material, often referred to as polycarbonate or plastic sheeting, offers several benefits when it comes to building greenhouses.

Advantages of Corrugated Plastic for Greenhouses

Corrugated plastic possesses numerous advantages that make it a popular choice for greenhouse construction. These benefits include:

- Lightweight: Corrugated plastic is much lighter than traditional glass, making it easier to handle and install.

- Insulation properties: Its multi-wall structure provides excellent insulation, helping to maintain a stable temperature inside the greenhouse.

- UV resistance: Most corrugated plastic sheets have UV inhibitors, protecting plants from harmful UV rays while still allowing sufficient sunlight to penetrate.

Durability of Corrugated Plastic

The durability of corrugated plastic contributes significantly to its viability as a greenhouse material. Here are some points regarding its durability:

- Impact resistance: Corrugated plastic is resistant to impacts, making it less likely to shatter compared to glass.

- Weather resistance: It can withstand harsh weather conditions including hail, rain, and strong winds.

- Longevity: With proper maintenance, corrugated plastic can last for many years, often outliving its warranty period.

Cost Effectiveness of Using Corrugated Plastic

Choosing corrugated plastic can be a financially wise decision for greenhouse construction. Consider the following cost-related factors:

- Lower initial cost: Corrugated plastic sheets are generally less expensive than glass panels.

- Reduced installation costs: Due to their lightweight nature, installation is quicker and requires less labor, further reducing costs.

- Energy savings: The insulation properties can lead to reduced heating costs during colder months.

Maintenance of Corrugated Plastic Greenhouses

Maintaining a greenhouse made of corrugated plastic is relatively straightforward. Here are essential maintenance tips:

See also:

- Regular cleaning: To maintain light transmission, it's crucial to clean the sheets periodically to remove dirt and algae.

- Inspection for damage: Regularly check for any cracks or wear and tear to prevent moisture intrusion.

- Reapplication of UV protectants: Over time, the UV inhibitors may degrade, so reapplying protective coatings may be necessary.

Considerations When Using Corrugated Plastic

While there are many benefits, there are also considerations to keep in mind when using corrugated plastic:

- Temperature sensitivity: Extreme temperature changes can warp the material if excessively exposed.

- Limited structural support: Ensure structural integrity by properly framing the greenhouse to prevent sagging.

- Potential scratching: The surface can be easily scratched, which may affect light transmission over time.

Can corrugated plastic withstand heat?

Corrugated plastic, often made of polypropylene, is known for its versatility and durability. However, its ability to withstand heat is a concern for many users in various applications. Generally, corrugated plastic can tolerate moderate heat but is not designed for extreme temperatures. Its melting point is typically around 160-170°C (320-338°F). Continuous exposure to temperatures beyond this range can cause the material to deform, melt, or lose its structural integrity. Thus, while corrugated plastic can handle some heat, it is essential to consider the specific temperature requirements of any intended application.

Understanding the Properties of Corrugated Plastic

Corrugated plastic materials possess various properties that make them suitable for multiple applications. However, their performance under heat is one of the crucial factors to consider. Key properties include:

- Lightweight: Corrugated plastic is significantly lighter than alternatives like metal or wood.

- Water-resistant: It is inherently resistant to water, making it ideal for outdoor use.

- Impact-resistant: The structure provides durability, but heat can decrease this strength.

Heat Resistance Limitations

In terms of heat resistance, there are clear limitations concerning corrugated plastic. Although it can endure light heat, repeated exposure can lead to failures. Important limitations include:

- Melting Point: The plastic begins to melt at relatively low temperatures compared to metals.

- Deformation: High temperatures can cause the material to warp or lose its shape.

- Reduced Lifespan: Continuous exposure to heat can degrade the material’s properties over time.

Applications of Corrugated Plastic in Heated Environments

Despite its limitations, corrugated plastic is still widely used in certain environments. Some applications successfully utilize its properties, including:

- Signage: Often used in temporary signs where they might encounter moderate heat.

- Construction Safety: It serves as barriers or safety fencing, minimizing exposure to high heat.

- Packaging: Often used for lightweight packaging solutions that do not encounter extreme heat conditions.

Alternative Materials for High Heat Applications

For applications requiring significant heat resistance, alternatives to corrugated plastic should be considered. These materials include:

- Metal Alloys: Provide excellent heat resistance but are heavier and more expensive.

- High-Temperature Plastics: Materials like polycarbonate or fluoropolymers can withstand higher temperatures.

- Fiberglass: Offers excellent heat resistance and strength for industrial applications.

Best Practices for Using Corrugated Plastic in Heat

To enhance performance and longevity, users should adhere to several best practices when using corrugated plastic in heated environments:

- Limit Exposure: Avoid direct long-term exposure to high temperatures.

- Ventilation: Ensure adequate airflow around the material to dissipate heat.

- Monitor Temperature: Regularly check the surrounding temperature to prevent overheating.

What type of plastic can I use for a greenhouse?

When selecting the appropriate plastic for a greenhouse, there are several options to consider, each with its own benefits and drawbacks. The most commonly used types of plastic for greenhouses are polyethylene, polycarbonate, and acrylic. Here’s a detailed overview of these options and their characteristics.

Polyethylene

Polyethylene is one of the most popular options for greenhouse covering. It is available in various thicknesses and can be used as a single layer or double layer for improved insulation. Some key features include:

- Cost-effective: It is generally cheaper than other types of greenhouse plastics.

- Flexibility: It can easily be stretched over frames, accommodating different shapes and sizes.

- Light transmission: Offers good light diffusion, essential for plant growth.

Polycarbonate

Polycarbonate is a more durable choice compared to polyethylene and is available in both single and multi-wall formats. This material provides better insulation and is resistant to UV radiation. Important aspects include:

- Durability: Highly resistant to impact and harsh weather conditions.

- Insulation: Provides excellent thermal insulation, helping to maintain a stable environment.

- UV resistance: Protects plants from harmful UV rays while allowing beneficial light to penetrate.

Acrylic

Acrylic sheets, often known by the brand name Plexiglass, are another option for greenhouse construction. They are lightweight and have great clarity. Key characteristics include:

See also:

- Clarity: Provides excellent light transmission and clarity for optimal plant growth.

- UV protection: High resistance to UV degradation, ensuring long-lasting quality.

- Weather resistance: Can withstand extreme temperatures and is less likely to yellow over time.

Choose the Right Thickness

The thickness of the plastic you choose is critical to your greenhouse's functionality. Different thicknesses can serve different purposes:

- 6 mil: Ideal for agricultural use; it offers good light diffusion and is easy to handle.

- 10 mil: Provides more durability and can withstand stronger winds and hail.

- 14 mil: Best for a more permanent structure requiring high strength and insulation.

Consideration of Local Climate

Your local climate significantly impacts the type of plastic you should use. Factors to consider include:

- Temperature: In warmer regions, you might prefer UV-resistant options to protect plants from extreme heat.

- Precipitation: In areas with heavy rain or snow, a sturdier material like polycarbonate is advisable for snow load resistance.

- Wind conditions: Strong winds may require thicker or more durable coverings to withstand potential damage.

Can you use clear corrugated panels for a greenhouse?

Yes, you can use clear corrugated panels for a greenhouse. These panels are often made from polycarbonate or PVC materials, offering several benefits that make them suitable for greenhouse applications. Their structure allows for effective light transmission, which is essential for plant growth, while also providing insulation and weather resistance. Below are some key advantages and considerations for using clear corrugated panels in a greenhouse setting.

Advantages of Clear Corrugated Panels

Clear corrugated panels provide various benefits as a greenhouse covering material. Some of these advantages include:

- Light Transmission: These panels allow an excellent amount of natural light to enter, essential for photosynthesis.

- Durability: Made from sturdy materials, they can withstand various weather conditions, including high winds and hail.

- Insulation: The corrugated design helps trap air, providing better insulation than traditional glass, which can help regulate temperatures.

Types of Clear Corrugated Panels

There are several types of clear corrugated panels available for greenhouse construction, each with unique characteristics:

- Polycarbonate Panels: These are known for their toughness, flexibility, and UV resistance, making them a popular choice.

- PVC Panels: Generally more affordable, they are lightweight and easier to install but may not provide the same level of insulation.

- Fiberglass Panels: These are another option that offers good light transmission but can yellow over time.

Installation Considerations

When installing clear corrugated panels for a greenhouse, it's essential to consider proper techniques for the best performance:

- Framing: Ensure the frame is sturdy enough to support the weight and wind load of the panels.

- Sealant: Use appropriate sealants to create a weather-tight seal, preventing leaks and heat loss.

- Angle of Installation: Install the panels at an angle to optimize sunlight exposure and drainage.

Maintenance of Clear Corrugated Panels

To ensure longevity and efficiency, the maintenance of clear corrugated panels involves:

- Regular Cleaning: Clean the surface regularly to prevent dirt buildup, which can reduce light transmission.

- Inspect for Damage: Periodically check for cracks or damage that could compromise the panel’s integrity.

- UV Protection: Consider using panels with UV protective coatings to extend their lifespan.

Cost-Effectiveness

Using clear corrugated panels can be more cost-effective than traditional greenhouse materials. Key factors include:

- Initial Investment: Often more economical to purchase and install compared to glass or other rigid materials.

- Energy Savings: Good insulation properties can lead to lower heating costs during colder months.

- Longevity: Durable materials mean less frequent replacement, reducing long-term costs.

Questions from Our Readers

Can I use corrugated plastic for a greenhouse?

Yes, you can use corrugated plastic for a greenhouse as it is a lightweight and durable material that provides good insulation. It allows sunlight to enter while also protecting plants from harsh weather conditions.

What advantages does corrugated plastic offer for greenhouses?

Corrugated plastic offers several advantages, including its UV resistance, energy efficiency, and ease of installation. This material helps maintain a stable temperature while minimizing heat loss, making it ideal for greenhouse environments.

Is corrugated plastic easy to maintain?

Yes, corrugated plastic is easy to maintain; it can be cleaned with simple soap and water to remove dirt or algae. Additionally, it does not warp or corrode like other materials, ensuring a longer lifespan with minimal upkeep.

Does corrugated plastic provide adequate light for plants?

Corrugated plastic is designed to allow a significant amount of natural light to penetrate, which is essential for plant growth. However, ensure you choose panels with appropriate light transmission properties to maximize photosynthesis in your greenhouse.

See also:

If you want to read more articles like Can I Use Corrugated Plastic for a Greenhouse? Pros, Cons, and Best Practices, we recommend you check out our Greenhouse category.

Leave a Reply

Related Articles